(1) Construction preparation

The preparatory phase of the asphalt concrete pavement construction includes the acceptance of the base layer, as well as the inspection of materials and mechanical equipment.

Base course acceptance: There are two types of base course: new construction and utilization of the original pavement. For high-grade highways, except for the construction of the first base layer adjacent to the soil foundation, which can be constructed by road mixing, the method of centralized mixing and mechanical paving shall be adopted for construction. In order to improve the flatness of the road surface, the construction is strictly carried out from the base layer to meet the various indicators required by the construction technical specifications. At present, in order to improve the quality of the project and reduce the cracks on the pavement, the upper base layer is often cut and laid with geogrid or geotextile spreading modified asphalt every 15-20 meters. Paving asphalt concrete on the original pavement should also be strictly checked and accepted, and the asphalt concrete pavement should be treated with potholes, subsidence, oil flooding, and concrete pavement chipping. For places with large waves, a layer of the mixture should be pre-laid on the depression and compacted, without considering the uniformity of the paving thickness.

Raw materials: Before mixing the asphalt mixture, various materials should be selected in strict accordance with the design documents and specifications. The source of materials, material quality, quantity, supply plan, material yard stacking and storage conditions must be checked. Coarse aggregates used in asphalt mixtures are usually composed of 2-3 different types of stones mixed. In the construction process, to ensure stable and qualified mineral graduation, it is required to ensure the consistency of different specifications of crushed stone particles in the process of stone feeding and receiving. Maintaining the consistency of the gradation composition of the asphalt mixture is very important to the stability of the various technical indicators of the asphalt mixture.

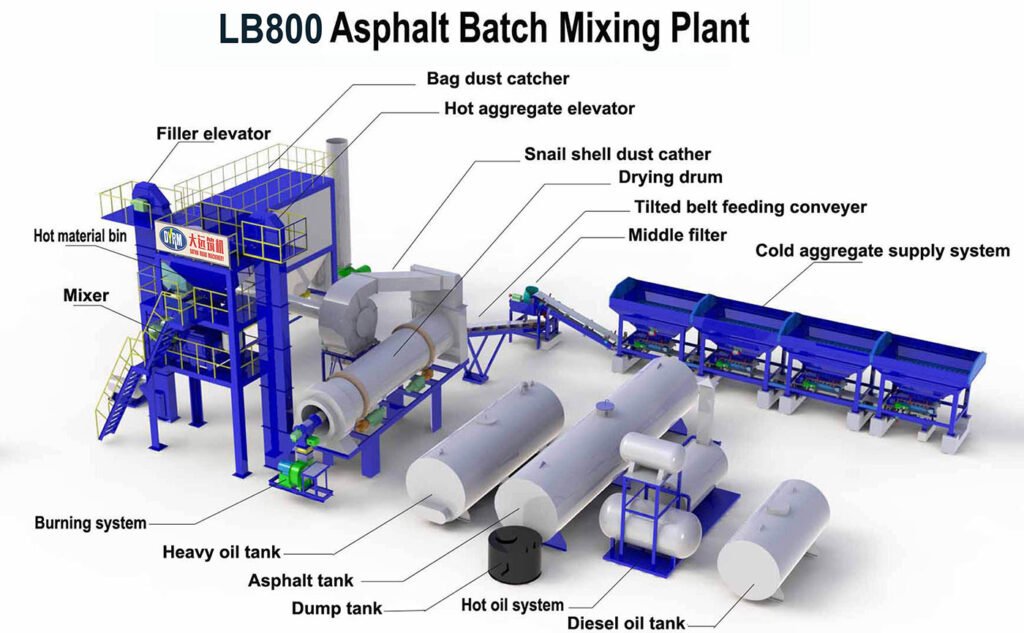

Construction machinery: Check the matching conditions, performance, and measurement accuracy of the mixing plant and asphalt pavement construction machinery and equipment before construction. Pay special attention to the accuracy of the electronic scale of the asphalt mixing plant before mixing. So as to ensure the accuracy of the proportioning of various materials such as aggregate, powder, and asphalt.

(2) Test section trial shop

The test section of the high-grade highway surface should be paved before construction. The length of the test section should be determined according to the purpose of the experiment, preferably 100~200M. The test section should be paved in a straight line. During the paving process of the test section, records and analysis should be done carefully, and first-hand construction data should be directly obtained. When constructing on the official road section, the construction shall be carried out in accordance with the test data obtained during the construction of the test section.

(3) Construction phase

The construction phase includes mixing, transportation, paving, joint treatment, and rolling of asphalt concrete mixture.

Mixing: Asphalt mixture must be mixed with mixing machinery in an asphalt mixing plant. It can be mixed with a batch mixer or continuous mixer. When engineering materials are supplied from multiple sources, sources, or quality is unstable, continuous mixers should not be used.

Transportation: The transportation of the mixture is carried by dump trucks with larger tonnage. When discharging from the mixer to the transport truck, the position of the vehicle should be moved every time a bucket of the mixture is unloaded to reduce the segregation of coarse and fine aggregates. Pay attention to tarpaulin during transportation for heat preservation, rain protection, and pollution prevention. The amount of asphalt mixture transporter should be more than the mixing capacity or paving speed to ensure continuous uninterrupted paving by the paver. Pay attention to the distance between the unloading material and the paver to prevent collision with the paver or falling outside the paver, causing uneven paving and affecting the smoothness of the road surface.

Paving: After spreading the penetration layer, the adhesive layer, and the lower sealing layer on the qualified base layer according to the regulations, the mixture can be spread. First, carry out construction stakeout. Accurate construction setting out avoids the severe influence of the reference steel wire, and the longitudinal spacing of the steel pillars should not be too large, generally 5 to 10 meters, and tighten with a wire tensioner. At the same time, it is necessary to strengthen the monitoring to prevent the disturbance of the on-site personnel and cause the fluctuation of the paving surface. Before paving, check the pillars, cross slope, thickness, and other indicators in time, and deal with the problems in time. The paving speed of the paver is constant and uninterrupted to reduce waves and construction joints. The test personnel check the proportion of the finished material and the asphalt content at any time, feedback to the mixing plant in time, and make adjustments in time. Designate a person to eliminate the segregation of coarse and fine aggregates. If the coarse aggregate nest is found, it should be eradicated and filled with new materials. This work must be carried out before rolling, and it is strictly forbidden to use the thin-layer patch method for leveling, so as to avoid the patch layer from falling off and crushing during use, causing the surface layer to move and crack.

Rolling: To ensure that the pavement reaches the designed compactness and good flatness, it is the main goal of the asphalt pavement paving and rolling stage. The key to achieving this goal is to make the asphalt mixture roll compacted at an appropriate temperature. Specially the initial pressure stage should be completed in a short time at a higher temperature within the temperature range required by the specification. This requires that the workload of the mixer and the paver in the construction organization must be matched per unit time, that is, the amount of mixing is slightly greater than the amount of paving so that the paving of the mixture is carried out under slow, uniform and continuous conditions, and Press until the edge is laid.