| Model & Capacity | Model: RMII Series [Match 40-240T/H AMP] |

|---|---|

| FOB Price | $5,000.00 – $200,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

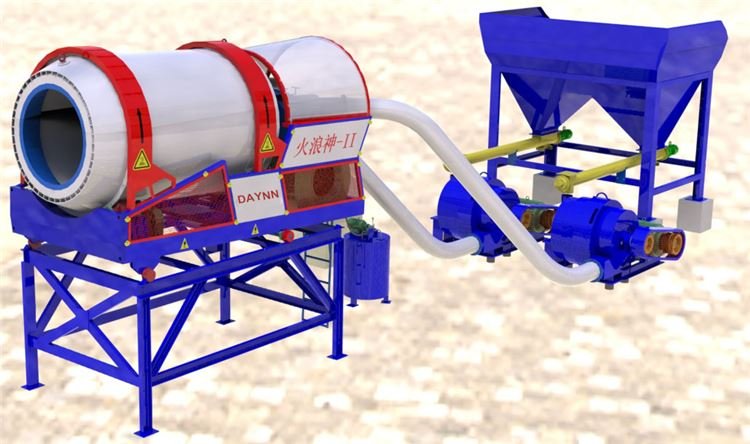

Composition of RMII series pulverized coal combustion device:

The pulverized coal-burning device is made up of a coal burner, coal canal, coal machine, screw conveyor, coal-fired storage, oil supply device, and operating system. The coal could be crushed by the coal machine, and sprayed into the coal burner, then will be burning by electron burning torch and oil.

Five main salient features compared with other common coal-burning systems:

1. Mechanized coaling: Loader coaling, lower labor intensity.

2. Automatic rotation: enhance the fireproof material service life.

3. Automatic walking: the burner can be moving by the motor drive at the stand.

4. Automatic ignition: There is an electron ignition device that can ignite automatically safely.

5. Automatic temperature self-control: It adopts a temperature regulation meter trailing the medium temperature and adjusting coal supply capacity in order to guarantee the medium temperature requirement.

Pulverized coal-burning device Main function and characteristic

Good adjustability for the blaze shape.

The different proportions of the burner wind inside and outside and the export jet stream type can adjust the air volume stepless, so that it could get the suitable flame shape in any working condition.

Combustion fully, energy saving

The coal-burning system can effectively reduce coal consumption because

Bating harmful gas emissions actively

There is a high-temperature flue gas back-flow forming negative pressure district in the head of the coal-burning system when it working, which can ignite powder coal quickly and make the temperature curve that follows the cylinder changes smoothly. Bating harmful gas emission actively.

Reasonable structure and good performance and characteristics overall

Good appearance, complete mating facilities, small resistance, frame adjustment flexibly and quickly.

New technology and material make it a long working life.

We use the special wear-resistant material or heat treatment technology for the common abrading section of the coal burning system, which makes the wearing life of the burner’s key position improve 5-10 times. The head and sprayer of the burner adopt wear-resistant steel material so that it has a long service life even under the condition of 1100ºC.

Equipped with a fuel supply device

The oil supply adjusts easily, and there is a special nozzle structure on the burning torch which has good atomization and ignition easily. High voltage spark ignition device, provide a key ignition, high ignition success rate.

Control pollution

Because the pulverized coal is fully burned and the harmful gas emission is small, the combustion tail gas passes through the dust collector, effectively controlling environmental pollution.

Cost savings

Due to high fuel prices, it is significantly lower the price of coal. This can save a larger cost for users and make the users earn costs in a large project in the same year.

Coal burner Competitive advantage

1. Main configuration

Fireproofing material: high-grade anti-strip made in China

Nozzle burner: special nozzle for fuel-burning system

Ignition device: high energy ignition torch

Coal crusher hammer:high-strength and wear-resistant alloy

Coal pipe:high-strength and wear-resistant rubber tube or thickening metal tube

Screw conveyor: high torque frequency conversion motor

Low voltage appliance: Domestic brands,

zhengtai appliance

Control button: Siemens APT

Transducer: Emerson

Temperature control device:

Importation wear-resistant hot resistance

2. The core technology

The automatic ignition device has a high effect. It can change low-voltage into high-voltage under the control system and use high voltage to make an electric spark in the head of the gun to realize igniting fuel atomization instead of traditional mode. Conveniently, safely and reliably.

Fuzzy control theory, automatic temperature control system, high accuracy, and automatic level, automatically adjust the amount of the coal supply under the heating temperature you set. Small fluctuation.

Burner internal use special patent structure make the frame stable. Combustion efficiency is not less than 90% and effectively reduces the harmful air emotion.

The coal crusher adopts a unique three-level crush structure that can guarantee Coal combustion particle size, and the hammer adopts high-strength wear-resistant composite material which improves the service life 3-5 times.

Specialization makes the production of the organization more reasonable. This effectively guarantees that the quality of the products and rapid production. A dramatic reduction in product delivery period.

Effective and efficient after-service is the strong support for users improving the construction progress.

Economic analysis (according to material price in China)

At present, for asphalt mixing plants, to heat aggregate, most of the fuel is diesel oil or heavy oil. But, with the increase of energy sources, fuel cost is becoming a big expends of asphalt batch mixing plants. Therefore, most contractors use coal as fuel instead of oil to reduce the cost. Now, we’re comparing the difference between coal burner and oil burner(take RD175 as a sample)

Under the standard conditions, RD175 works one hour normally, the capacity of 160t, heavy oil consumption is 6.5kg/ton, coal consumption is 10kgs/ton, the price of heavy oil is RMB3,300/ton, for coal is RMB950/ton, power price is RMB1.15/degree.

Oil burner adopts Italy : drawing fan power: 37kw; oil pump: 2.2kw; oil heater: 30kw. Air compressor: 15kw.

Coal burner adopts Roady RMII2000-00, coal crusher: 2x45kw;coal screw: 2×1.5kw(frequency timing); burning power: 19.4kw; oil supply: 1.5kw; vibrator power: 0.25kw;

When using oil burner: power consumption: 84.2kw/h

Cost on power: 84.2×1.15=96.83

Oil consumption: 160×6.5=1040kgs

Cost of oil: 3300×1.04=3432

At this condition, burning system cost is:

96.83+3432=3529/h

When using coal burner, power consumption: 113kw/h

Cost of power: 113×1.15=130

Coal consumption: 160×10=1600kgs

Cost of coal: 950×1.6=1520

At this condition, burning system cost:

130+1520=1650/h

By comparison, we easily find that the cost of RD175 working one hour, cost of using coal is 1779(3529-1650=1779) less than using oil, then will save around 20,000 per day. Therefore, adopting coal burners can reduce the cost greatly and bring more benefits to customers. In summary, Our RM series coal burner is a wise choice for customers to reduce costs.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.