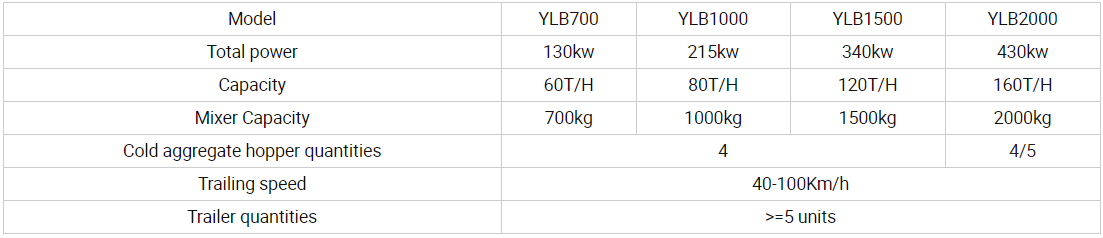

| Model & Capacity | Model: YLB Series [40 – 160 T/H] [500 – 2000 KG/BATCH] |

|---|---|

| FOB Price | $40,000.00 – $600,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

Specifications of 40-160t/H Mobile Asphalt Mixing Plant

Application range: Mainly used in the construction of airport runways, ports, highways, and bridges. It is an ideal choice for emergency construction of special roads.

Main advantage

• Rated output: 60 tons/hour to 160 tons/hour

• Pre-installation and testing have been carried out before leaving the factory

• Only 6 semi-trailers for transportation

• Fast and easy on-site installation

• Various devices can be added

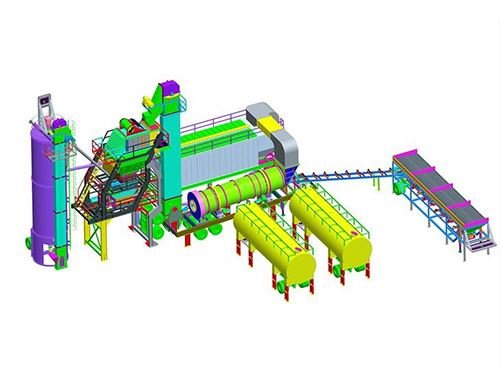

Mobile type Aggregate supply system

The feeding bucket and aggregate belt are mounted on a mobile chassis.

The belt feeder adopts frequency conversion speed regulation, which has a large speed range, stable and efficient operation.

The collection hopper is equipped with an alarm device to warn that there is no aggregate in the hopper.

The fine silo is equipped with a silo wall vibrator to avoid clogging.

There is a screen on the top of each hopper to prevent larger aggregates from entering, thus ensuring the reliability of the system.

Mobile type Drying drum system

The mobile drying drum uses 4 friction wheels, driven by four synchronous motors. It runs smoothly and has low noise.

The temperature of the dried aggregate directly affects the temperature of the final product. Drying efficiency directly affects fuel consumption, so a reasonable structure is very important. We have fully absorbed foreign advanced hybrid technology, achieved satisfactory results, and achieved the expected goals.

Mobile type mixing tower

The mixing building includes a vibrating screen, a hot aggregate bin, a mixer, asphalt weighing, and filler weighing. All these components are mounted on a trailer chassis. Very easy to install and transfer to other construction sites.

The reducer of the mixer selects internationally renowned brands.

The mobile dust removal system

The dust removal system is a two-stage dust removal system, a first-stage gravity dust collector, and a second-stage bag filter. All collected recycled materials are transported to the hot aggregate elevator for recycling.

Two-stage bag filter. The bag is made of Nomex high-temperature resistant material. It can work underrated high temperature, has a long service life, and the dust collector efficiency can reach more than 99%, which fully meets environmental protection standards.

Mobile control system

The electrical control adopts a box-type control cabinet, and the main components are Siemens, Schneider, or ABB and other internationally renowned brands, with interlocking and secondary protection; the large motor adopts a reasonable step-down start; the console is equipped with an emergency manual control operating device With aggregate scale, powder scale and asphalt scale digital display, color touch screen and Japanese Omron PLC controller, it can realize automatic, semi-automatic and manual control; configure the printer to print reports;

The control room and diesel tank are installed in the same rack to make full use of the track layout.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.