| Model & Capacity | Model: HZS90 [90T/H] |

|---|---|

| FOB Price | $5,000.00 – $200,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

| Model | HZS90 | |

| Rated productivity(m³/h) | 90 | |

|

Mixer |

Model | JS1500 |

| Aggregate size | Φ100 mm | |

| Power | 2×30kW | |

| Cycle period | 60 S | |

| Mixer capacity | 1500 L | |

| Batching machine | Batching capacity | 2400L |

| The largest aggregate particle | 80 mm | |

| Aggregate bin capacity | 4×12m3 | |

| Conveyor productivity | 500T/h | |

|

Weighing range and accuracy |

Aggregate | (0~2000 kg)±2% |

| Cement | (0~900 kg)±1% | |

| Fly ash | (0~500 kg)±1% | |

| Water | (0~400 kg)±1% | |

| Admixture | (0~50 kg)±1% | |

| Filler bin capacity | 4×100 T | |

| Maximum productivity of screw conveyor | 80 T/h | |

| Unloading height | 4.1 m | |

| Installed Power | 172 kW | |

HZS90 Concrete Mixing Plant Product Details

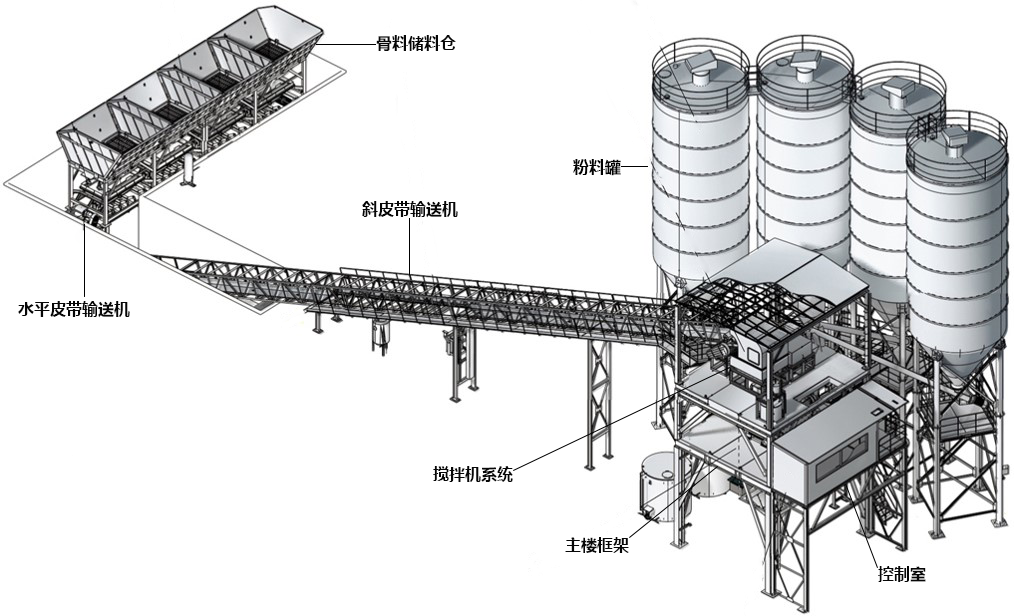

Concrete mixing plant manufacturers continue to innovate the design concept of concrete mixing plant, which provides great convenience for concrete production enterprises that need to transfer production. HZS90 concrete mixing plant is composed of conveyor belt, cement silo|cement tank, screw conveyor, PLD batching machine, twin-shaft mixing host, intelligent computer control room, and metering system.

Configuration instructions

1. Aggregate supply system (3×16m3)

*Total volume of aggregate bin: 48 m3, divided into 3 identical bins, each bin has a volume of 16 m3.

*Each aggregate bin is equipped with 2 unloading doors to realize coarse and fine weighing. Airtac or Jiefit series cylinders and solenoid valves are used as actuators.

2. Inclined belt conveyor

*The frame is a large angle steel truss type with a support frame in the middle.

*The inclination is 200, the length of the belt conveyor is about 40 meters, and the tensioning device is equipped.

*Five-layer nylon rubber belt, thickness 10mm, width 800mm, length about 90 meters, conveying capacity 600t/h.

3. Mixer

*JS1500 twin-shaft mixer.

*The steel structure of the main machine is made of large rectangular tubes and thick steel plates, forming a rigid frame structure.

*The shaft end seal adopts labyrinth and floating seal ring seal.

4. Mixing Tower

*The discharge height is 4 meters.

*The height of the mixer support platform is 5.5m, and the channel width is greater than 4.2m.

*The pillars of the main building are made of steel pipes with a diameter of 273, which are rigid. The platforms and beams are made of H-shaped steel (300×390) and 28b and other large channel steels.

5. Water metering system

*1 water metering hopper with a volume of 0.35m3. The water metering can be used for coarse and precise weighing through the fine weighing silo. The bottom discharge is controlled by a pneumatic butterfly valve with a diameter of φ150 (WAM).

*3 load cells.

6. Cement measurement system

*1 cement metering hopper with a volume of 0.7m3, installed above the mixer, the bottom discharge is controlled by a pneumatic butterfly valve, the diameter of the pneumatic butterfly valve is φ250, and it is equipped with a vibrator.

*3 load cells.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.