| Model & Capacity | Model: LB1200 [105T/H] [1250KG/BATCH] |

|---|---|

| FOB Price | $255,000.00 – $300,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

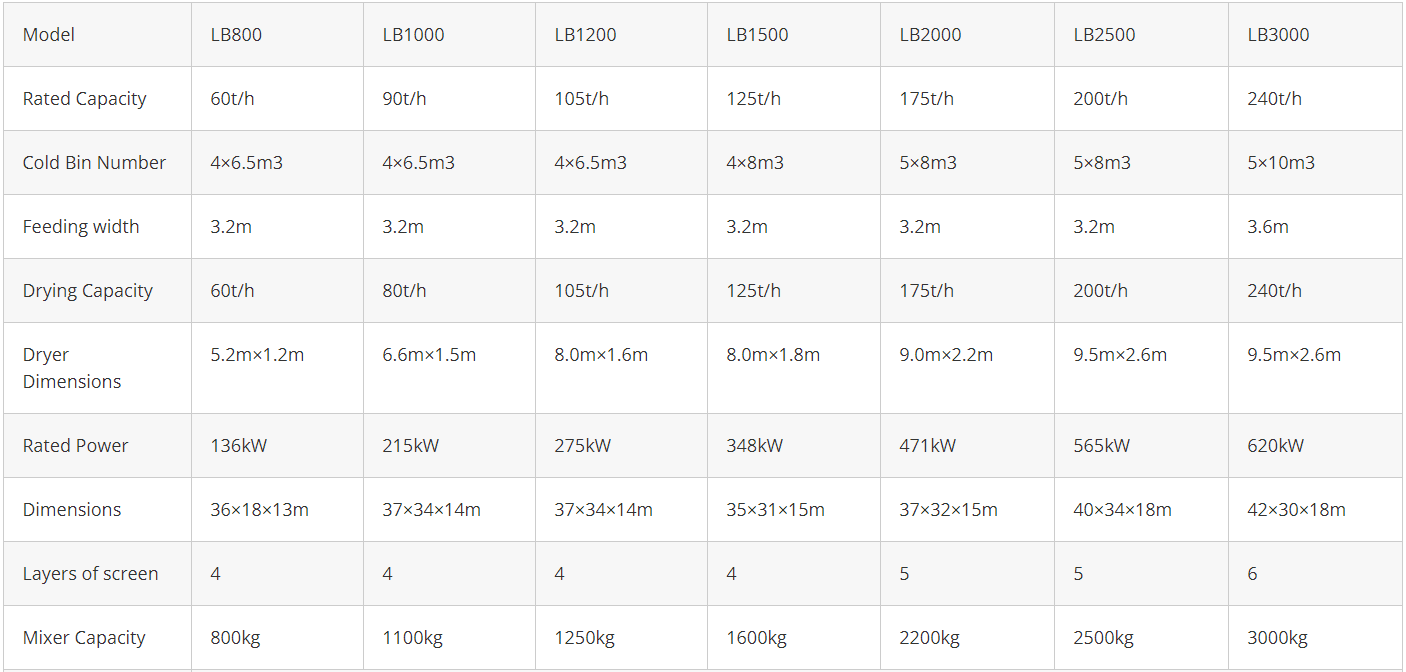

| Model | LB1200 Asphalt Mixing Plant |

| Capacity | 105t/h (under standard working condition) |

| Mixer Capacity | 1250kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 37 × 34 × 14m |

LB Series Asphalt Mixing Plant Specifications

The hourly output of the LB1200 asphalt mixing plant is 90-105 tons. With complete configuration, excellent performance, and safety, it can meet high-grade highways’ construction, the transition is flexible and convenient, and the price is cheap. Choosing this product will give you unexpected gains.

Cold aggregate system

The individual hoppers with large volume capacity are available to the customer for material classification. The wide loading of each hopper enables smooth and effective feeding. The conveying belt has a frequency controlling device. It can control the feeding speed efficiently. The material shortage warning indicator can avoid free material in the hopper.

Drying Drum System :

For the manufacture of asphalt mixture, it is essential to remove the moisture from the cold aggregate to ensure bonding with the asphalt. In order to attain the optimum heating results, the dryer drum has an insulating layer to prevent heat loss. The compact drum is easy to operate and maintain.

Mixing system

The mixing system is one of the important components of the asphalt mixing plant. The drum type integrates the drying drum and mixing drum together. The inner side of the drum has welded with mixing blades, which can produce a homogenous mixture. While the batch-type asphalt plant has a separate mixing bin in the mixing tower. The mixing cycle only takes 45 seconds. With a large mixing capacity, there is a heavy burden on the mixer. Therefore, the stationary asphalt mix plants are manufactured with high wear-resistant materials to guarantee the durability of plants.

Vibrating Screen

The stationary asphalt batching plant has a vibrating screen to distinguish particle sizes of hot aggregate. The vibrating screen has equipped with multiple screens to ensure accurate weighing and high-quality mixing. The vibrating screen is tightly sealed to prevent dust from overflowing. The high-strength manganese materials with a reinforced rim can prolong its life span.

Dust Collector

The adoption of the Nomex needle felt can prove water and oil. The layout of the filter bags guarantees utilization of the surface area with efficient filter function. The outside of the dust remover has an insulating layer to avoid bag condensation. The heat-resistance filter bags have a long service life. The particle sizes of dust can be adjusted to meet different formulation requirements.

Asphalt Supply

The asphalt tank and pipes have an insulating layer with small heat loss. The asphalt is installed liquid level and temperature display device, which is convenient to operate. The complete automatic control system of the conduction oil furnace can be operated independently.

Features Of The Stationary Asphalt Mixing Plant

1. The stationary asphalt mixing plant is manufactured in container units with a modular design, which makes easy installation.

2. There is wide space around making for convenient access and easy maintenance.

3. The equipment has the automatic diagnosis function, which can monitor the working conditions in time and rule out unnecessary failures.

4. Frequency controlling device is applied to many components. The processes can be controlled and adjusted in synchronized proportion.

5. The adoption of international brands makes pneumatic components reliable performance and long service life.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.