| Model & Capacity | Model: LB1500 [125T/H] [1600KG/BATCH] |

|---|---|

| FOB Price | $230,000.00 – $320,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

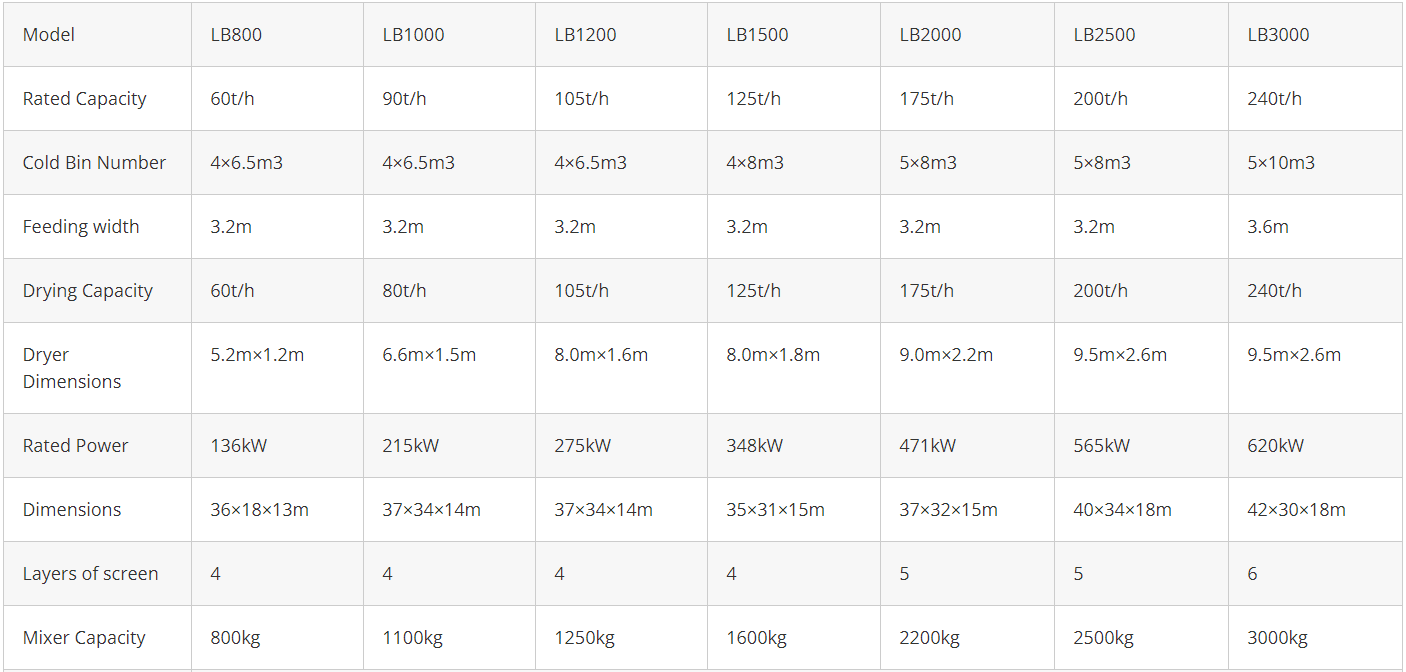

| Model | LB1500 |

| Capacity | 125t/h (under standard working condition) |

| Mixer Capacity | 1600kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 35 × 31 × 15m |

LB Series Asphalt Mixing Plant Specifications

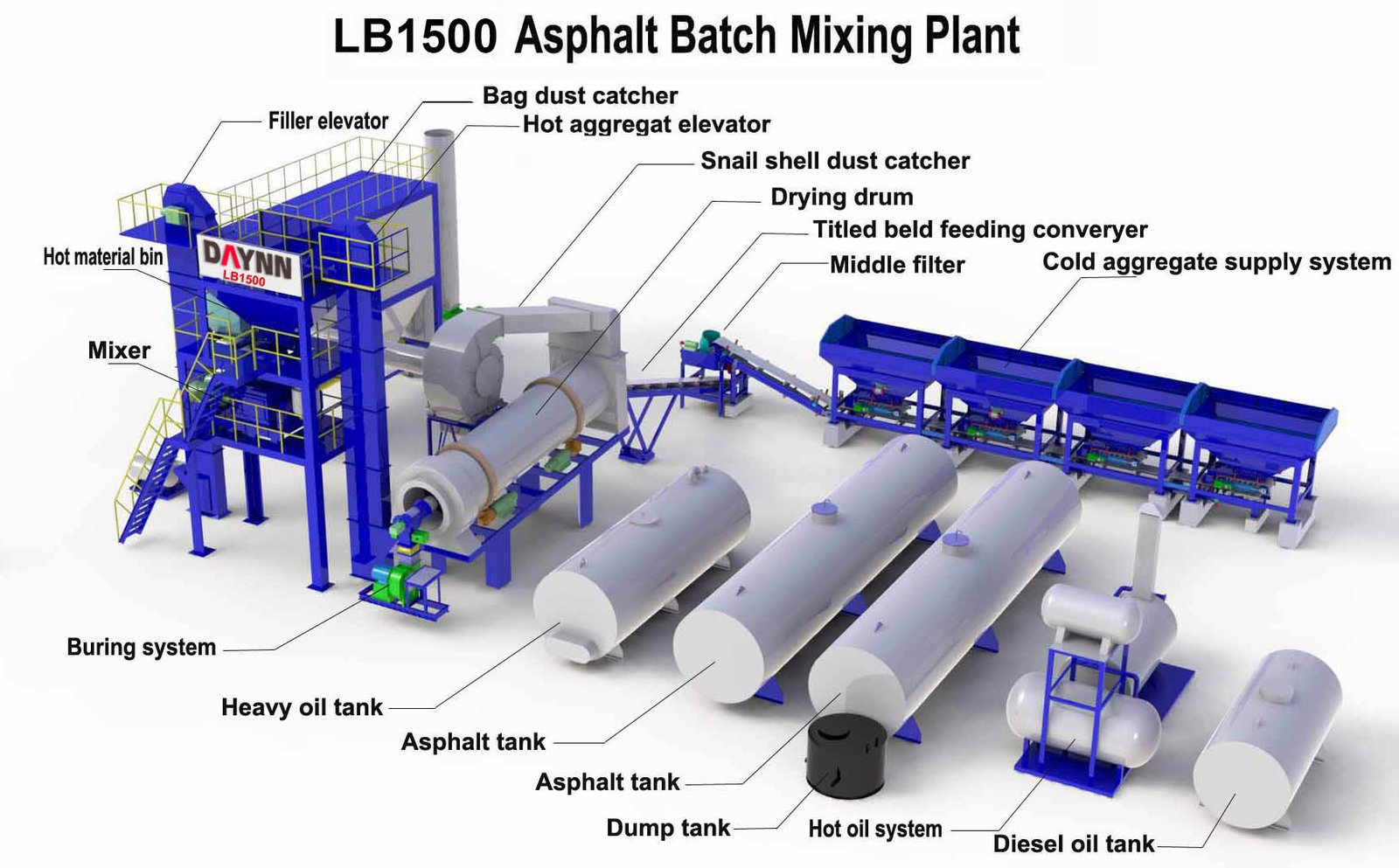

LB1500 asphalt mixing plant is a batch-type forced asphalt mixing equipment designed and manufactured by Daynn Road Machinery. Modular design, easy to transport, simple operation, convenient maintenance, and at the same time has the same working performance as large-scale asphalt mixing equipment; energy saving, small footprint, low failure rate.

The composition of the LB1500 asphalt mixing plant

The plant is composed of a cold aggregate supply system, dry heating system, hot stone material lifting system, screening and weighing system, mixing system, powder system, dust removal system, asphalt supply system, control system, and other systems. The components of key parts are assembled with imported products. The whole set of equipment has stable and reliable operation performance, with an hourly production capacity of 125 tons. Using PC+PLC intelligent automatic control, it can meet the needs of high-grade roads.

Features of LB1500 asphalt batching mix plant

Modular cold aggregate supply system with synchronous proportional automatic control and adjustment,

A high-efficiency and energy-saving drying and heating system with a heat exchange efficiency of 90%,

High-strength plate chain bucket lifting system with the 0-decibel silent check,

Screen quick change, intelligent induced air pressure relief and maintenance-free screening system,

High-precision weighing system with good stability and automatic error compensation,

15% overproduction redundant design of uniform, high-efficiency, large-circulation three-dimensional boiling mixing system,

Efficient environmental protection bag dust removal system with exhaust emissions far exceeding national standards.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.