| Model & Capacity | Model: LB2000 [175T/H] [2200KG/BATCH] |

|---|---|

| FOB Price | $465,000.00 – $560,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

| Model | LB2000 Hot Mix Asphalt Plant |

| Capacity | 175t/h (under standard working condition) |

| Mixer Capacity | 2200kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 37 × 32 × 15m |

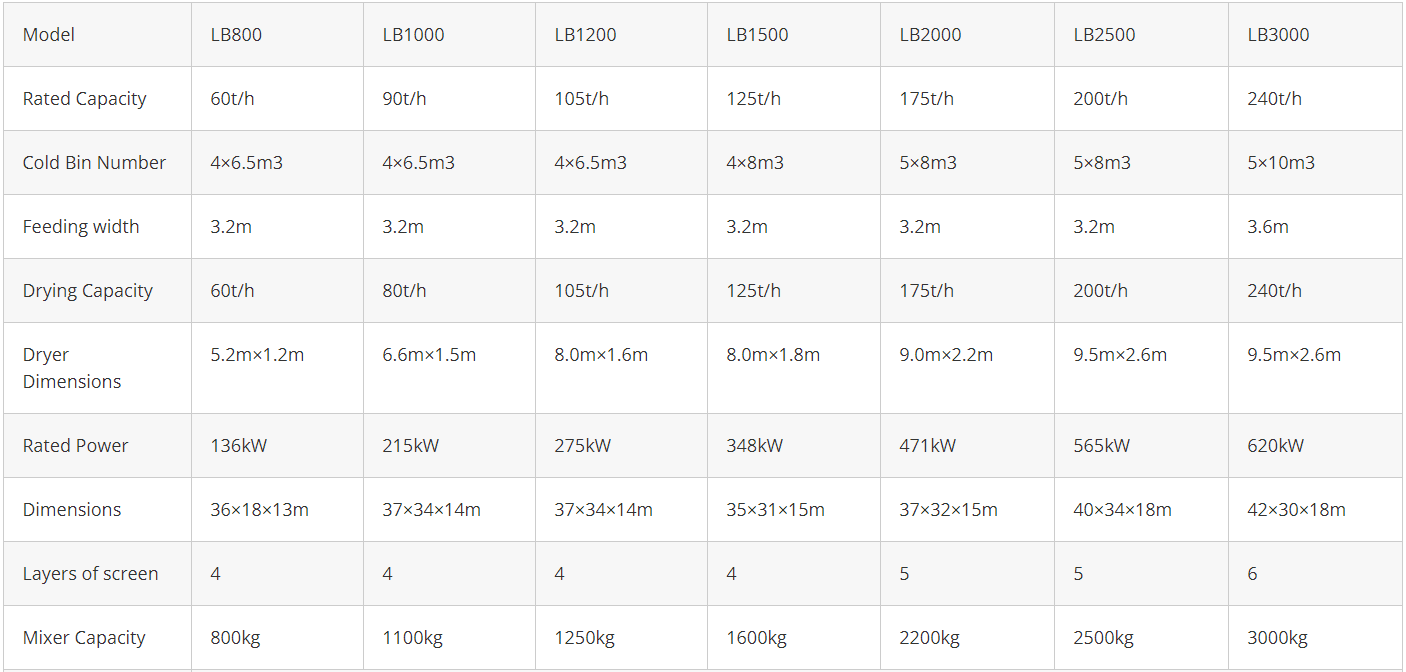

LB Series Asphalt Mixing Plant Specifications

Asphalt mixing plant can also be called asphalt concrete mixing plant, hot asphalt mix plant, or asphalt plant for short. It refers to the equipment that dries, heats, screens, and measures the sand and gravel, and adds an appropriate amount of filler (stone powder), and mixes it with the hot asphalt liquid in a certain mixing ratio to form an asphalt mixture. According to the mixing method, it can be classified into the forced batch type and continuous production type; according to the moving method, it can be classified into stationary type, semi-fixed type, and mobile type. It is necessary equipment for building expressways, graded roads, municipal roads, airports, and ports. Daynn asphalt mixing plant has excellent production capacity (high output), advanced control system, stable, reliable, accurate, and efficient compared with other hot mix plants. Our asphalt batch mix plants are low energy consumption, high efficiency, environmental protection, and energy-saving.

Asphalt mixing equipment is mainly composed of the aggregate supply system, drying heating system, burning system, lifting system, screening system, hot aggregate storage system, weighing and mixing system, asphalt supply system, filler supply system, dust removal system, finished material storage, and Control system and other parts.

Drying Drum & Burning System :

The outside diameter of the drum is wrapped with a 50mm thick insulation, and aggregate lifting flights that assist the heat exchange between aggregates and flame are installed inside the dryer drum, which enables the drum dryer to reach maximum heating efficiency.

The drum is driven by four friction rollers and universally connected, which features smooth drive and evenly distributed forces.

Fuel/Coal Burner

The burner is equipped with a gas ignition device, and the fuel is automatically adjusted in a ratio of 1:3. The burner can use heavy oil, light oil, gas, and coal as the fuel given their availability and costs.

Dust Collector System :

Components

Primary Screw Conveyor, Cyclone Separator, Secondary Screw Conveyor, Baghouse &Chimney.

BagHouse

The bag is made of imported Nomex needled felt, which is waterproof and oil resistant. The dust cake removal is automatically controlled and the pulse jet method is used to clean the bag. The baghouse has the functions of over-temperature alarming and dust recycling.

Mixing Tower Assembly System :

Vibrating Screen: Multiple deck screens with standard mesh sizes such as 37.5×37.5, 25×25,12×12, and 5×5, or built according to customer’s requirement.

Weighing Hoppers & Hot Aggregate Hopper

Composed of aggregate weighing hopper, filler weighing hopper, and bitumen weighing hopper. The Toledo sensor is used, which features accurate measuring and automatic error compensation.

Pugmill type Mixer

The pugmill is manufactured with European technology, uses synchronous gears and pneumatic rotating gates. The mixer is driven by double reducers, with two shafts rotating in the counter direction, which makes the aggregates turn up and down and swivel in-plane to achieve a homogeneous mixture.

Hot Aggregate Elevator & Filler Supply System :

Hot Aggregate Elevator

It uses a double row double ear plate chain for smooth elevating and slide-type buckets for efficient elevating. The special design of aggregate exit reduces wearing and noise.

Filler Supply System

The filler supply system consists of a filler elevator, a filler silo, and a screw conveyor. The filler silo breaks the agglomeration pneumatically.

Asphalt Supply System :

Bitumen Weighing and spraying device. A high-pressure bitumen pump is used to enable the quick and even mixing of hot aggregates, fillers, and bitumen, and increase output.

Bitumen storage and transfer

The bitumen supply system consists of a heat-conducting oil boiler, bitumen tanks, an oil discharge vessel, a light oil burner, bitumen pumps, pipes, and valves.

Electric Control System :

Control Room

Designed like a container, air-conditioned, ergonomic operation panel.

Electric control Parts

International brands ensure the reliability of equipment.

Electric Control System

Convenient, reliable, simple, and accurate control

With fault-detecting and diagnosis alarming function, the weighing error can be automatically followed and compensated. Real time and dynamic display of production process.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.