| Model & Capacity | Model: LB4000 [320T/H] [4000KG/BATCH] |

|---|---|

| FOB Price | $900,000.00 – $1,600,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

| Model | LB4000 Bitumen Mixing Plant |

| Capacity | 320t/h (under standard working conditions) |

| Mixer Capacity | 4000kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 51 × 50 × 21m |

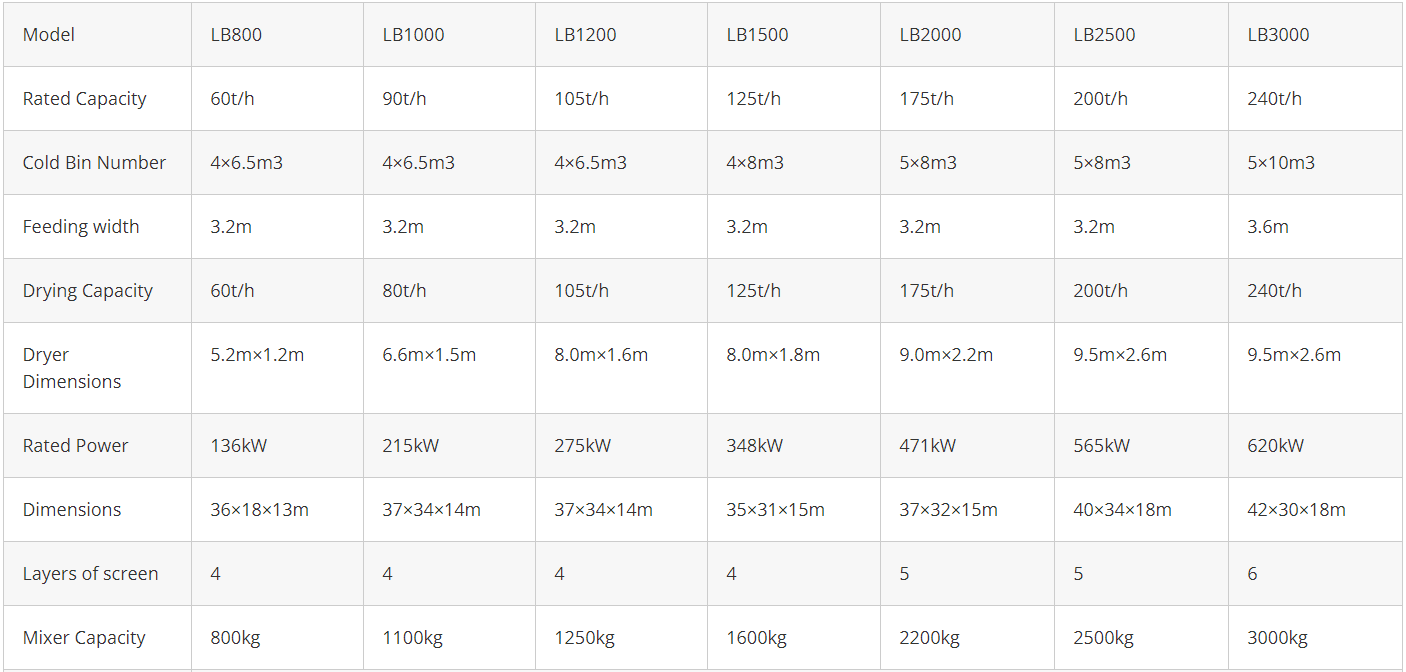

LB Series Asphalt Mixing Plant Specifications

Structural characteristics of LB4000 bitumen mixing plant

The overall layout is compact, the structure is novel, and the floor space is small, which is convenient for installation and transition.

Outstanding performance, high-cost performance, and is not restricted by region and climate. It can be used all over the world. Our bitumen Mixing Plant adopts a mixing tower module structure, convenient transportation, strong expansion ability, multiple interfaces, and adopts mature and reliable advanced technology.

Aggregate feeder

Composition: The aggregate feeder is composed of a collecting hopper, a feeder, and a cold aggregate conveyor. The number and volume of the hopper will vary according to the needs.

Function: Continuously and evenly send cold aggregate to the middle filter screen for filtering.

Drying drum

Composition:1. Feeding box; 2. Movable ladder; 3. Front leg; 4. Front roller; 5. Cylinder; 6. Rear roller; 7. Rear support leg; 8. Unloading box;

Function: Heat all kinds of aggregates evenly to a certain temperature and send them into the hot aggregate hoist from the discharge port.

Burner

Composition: 1. Burner body, 2. Blower, 3. Oil circuit, 4. Oil injection pump, 5. Burner platform, 6. Ignition system, 7. Control system;

Function: Mainly provide the heat source required for heating the cold aggregate to the drying drum.

Mixing Tower

Composition: 1. Top guardrail assembly 2. The climbing ladder assembly 3. Hot bin layer frame assembly 4. Mixing tank layer frame assembly 5. Bottom leg assembly

Function: Provide overall support for related equipment components. The mixing plant is the core supporting part of the complete mixing equipment.

Dust removal system

Composition:1. Volute bracket 2. Air mixing valve 3. Bag dust collector 4. Primary screw conveyor 5. Volute dust collector 6. Air escape valve 7. Lower hopper 8. Secondary screw conveyor 9. Induced air system.

Electrical control system

Composition: 1. Electrical control room 2. Electrical control cabinet 3. Touch screen operating system

Function: It is the core component that controls the operation of the entire set of equipment and electrical components.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.