| Model & Capacity | Model: LB500 [40T/H] [500KG/BATCH] |

|---|---|

| FOB Price | $66,000.00 – $146,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

| Model | LB500 Asphalt Batch Mix Plant |

| Capacity | 40t/h (under standard working conditions) |

| Mixer Capacity | 500kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 35 × 18 × 12m |

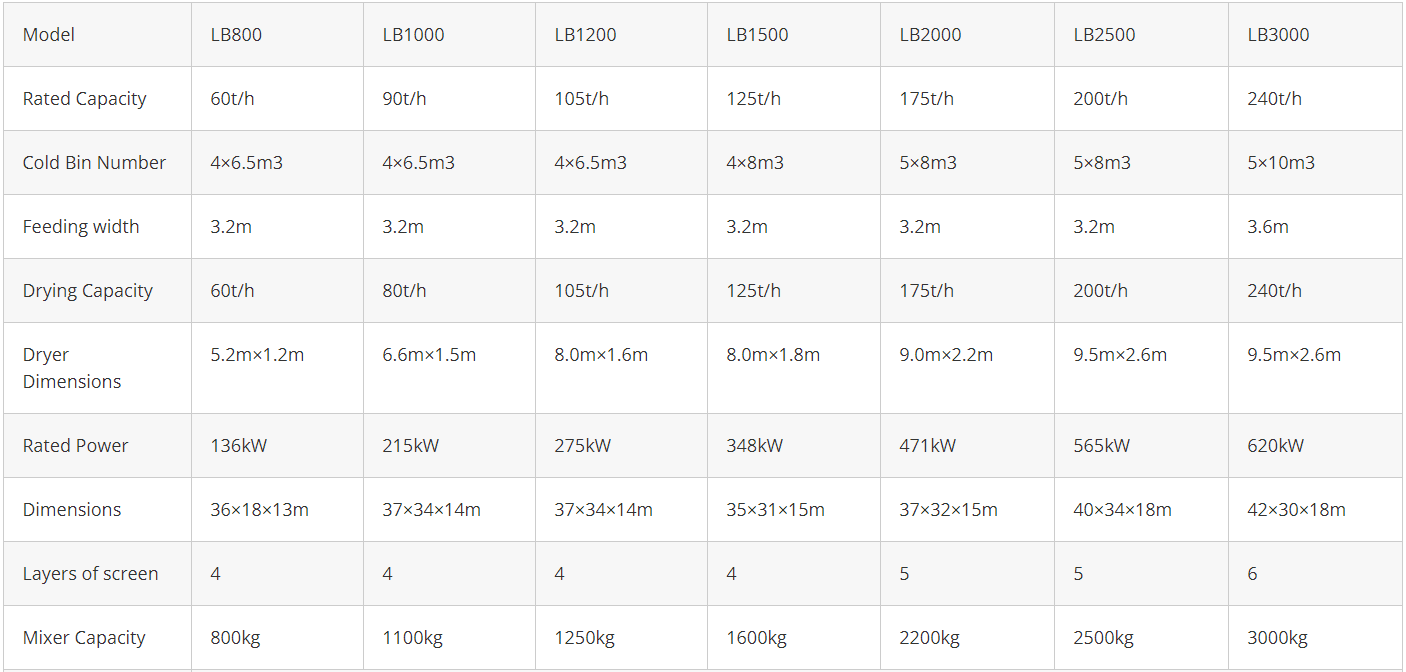

LB Series Asphalt Mixing Plant Specifications

Warmly welcome to visit our factory!

LB500 is a new generation of batch asphalt mixing plant developed by introducing foreign technology. It has the advantages of stable performance, environmental protection and energy-saving, and convenient transportation and transfer. It is ideal for highway, airport, port, water conservancy, and other road construction equipment.

Cold aggregate system

1. Based on frequency conversion speed regulation, the speed can be adjusted accurately according to the output setting and ratio requirements;

2. Automatic alarm device for lack of material detection; safety emergency switch;

3. Modular design makes installation and disassembly more convenient.

Drying Drum System :

1. Brand new design, using a patented power drive structure, effectively reducing power consumption.

2. The blades inside the drying drum are specially arranged so that the material curtain formed by the material is uniform and the heat exchange efficiency is high.

3. The quality is guaranteed, meets customers’ different construction needs to the greatest extent, and creates huge economic benefits for customers.

4. The combustion chamber is built-in, and the baffle plate is specially designed. The milled material does not directly touch the flame, which is safer.

Vibrating Screen system

1. The double-axis linear vibrating screen is efficient and practical, with an external vibrator, energy-saving, low noise, and simple maintenance;

2. Optimized design of vibration inclination and sufficient screening area to ensure strict gradation ratio and screening efficiency;

3. 24 hours Test before leaving the factory to ensure the stability of the screening system;

4. Vibrating screen bearings are selected from internationally renowned brands resistant to high temperature, vibration, and long life.

Metering system

1. Synchronous measurement technology of double bins for aggregate, increasing the measurement speed by 50%;

2. Adopt dynamic and precise control secondary measurement technology, high measurement accuracy;

3. Automatic drop compensation, overweight alarm, automatic lock, automation and effortlessness.

Mixing system

1. Designed and manufactured in accordance with European standards. The service life and overload capacity of asphalt concrete mixer exceed national standards;

2. Two shaft-mounted deceleration motors are independently driven, gears are synchronized, and the work is more stable;

3. The blade structure and layout have been carefully designed and repeatedly verified.

4. With international standard high-strength wear-resistant alloy materials, the working life of the mixing blades are more than 100,000 batches.

5. The high-pressure spraying asphalt pump and the grid-type powder feeding mechanism greatly shorten the mixing time and improve the mixing efficiency.

Control System

1. Using foreign advanced micro-control technology, and PLC, PC computer control equipment;

2. The control program with independent intellectual property rights and the dual-computer redundant design ensures the reliable operation of the system;

3. The control components adopt products from Siemens, Omron, Emerson, etc., which are trustworthy;

4. The man-machine interface is more humane, and the whole production process can be controlled and managed through the man-machine interface.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.