| Model & Capacity | Model: LB800 [60T/H] [800KG/BATCH] |

|---|---|

| FOB Price | $104,000.00 – $156,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

| Model | LB800 Asphalt Mixing Plant |

| Capacity | 60t/h (under standard working conditions) |

| Mixer Capacity | 800kg/batch |

| Environment Noise | ≤80db(A) |

| Operation | Fully automatic/manual operation |

| Voltage | 220V/380V, 50Hz (adjustable) |

| Dimensions (L × W × H) | 36 × 18 × 13m |

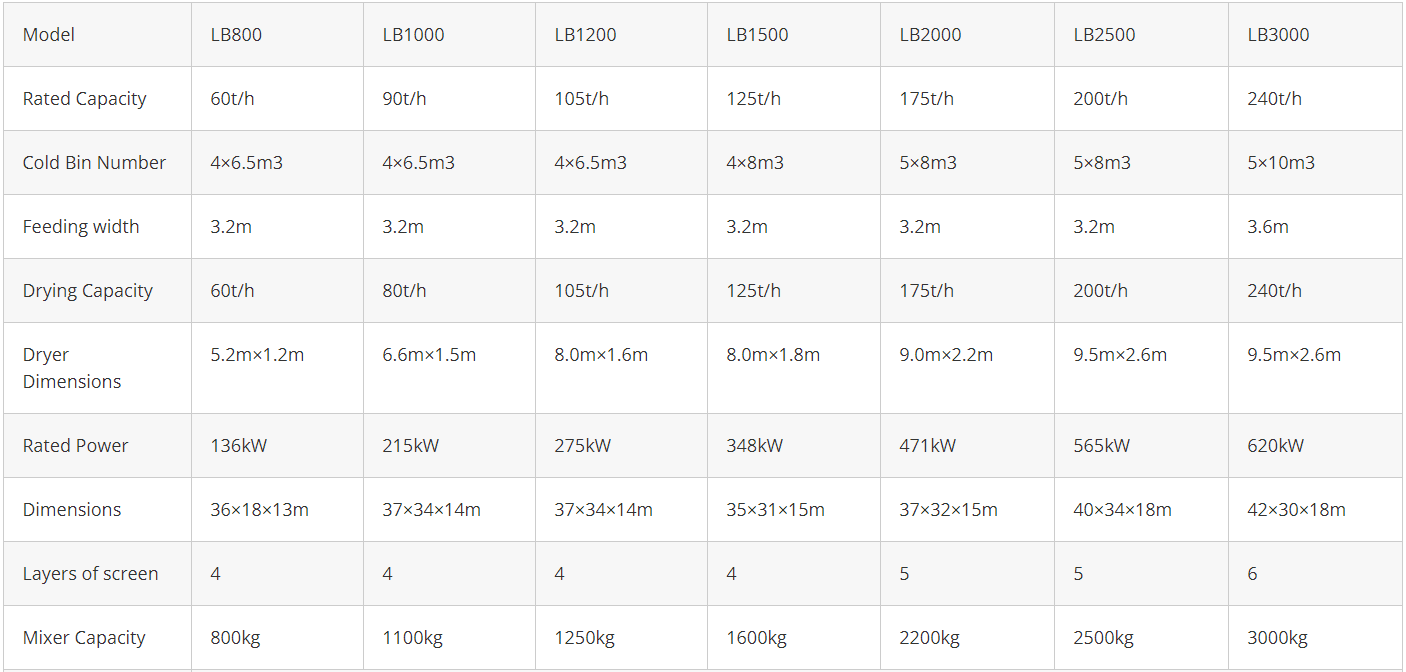

LB Series Asphalt Mixing Plant Specifications

Warmly welcome to visit our factory!

LB800 asphalt mixing plant can meet the needs of the rapid development of road construction and high-grade road maintenance. It has a high level of large output, fast transportation, and convenient installation, and meets the national environmental protection requirements.

Cold Aggregate Feeding System

1. Each hopper is equipped with a belt conveyor controlled by frequency converters. More Energy-saving.

2. Bin-wall vibrators are mounted on the wall of sand hoppers to ensure the materials feeding.

3. A screen on the hopper is to prevent oversize materials from getting into the dryer drum. The feeder bin system is mounted with a pulling switch for personnel safety.

4. Equipped with no aggregate alarm device.

Drying Drum

1. The drum body is designed for high efficiency and energy saving.

2.The drying drum can be equipped with a fully automatic burner (diesel, heavy oil, and gas as fuel options).

3.The steel plates of dryer blades are highly wear-resistant and heat resistant.

4.Driving system of the drum dryer can adopt international brands like Nord or Siemens brand motor and Rossi gearbox according to your requests.

Mixing Tower Assembly

1. Hot Aggregate and Filler elevator.

The edge of the bucket is strengthened by the intensified panel, wearable iron rods are fixed at the inlet.

2. Mixing System

The asphalt mixer adopts a special twin shaft design. The mixing arms are symmetrically crossed to ensure high-speed, affection, and mix quality. The liner boards, paddles, and arms are made of high chromium and high molybdenum materials. Easy to be adjusted and changed. German brand Nord motor and gearbox are optional.

3. Vibration Screen

With double vibrating motors and a compulsory vibrating screen, the passing rate reaches up to 95%. 48-hour non-stop inspection with CSI digital vibrating tester is conducted before ex-works. vibrating screen structure adopts reasonable design, started by maintenance-free vibrating motor, easy for replacement of screen mesh and daily maintenance.

4. Weighing System

The weighing system includes aggregate weighing, filler weighing, bitumen weighing. There is an internationally famous brand like Mettler Toledo for your choice.

Dust Collecting System

1. Adopting two stages of dust collecting system (gravity filter + baghouse filter)

2. High and low-temperature protection device ensures the system security.

3. The filter bags are made of NOMEX material with high-temperature resistance. The emission can be less than 20 mg/Nm³.

4. Temperature sensors are installed to protect the filter bags from over-heated and moisture condensation.

Control Room and Control System

1. Sound insulation, heat insulation

2. Air container, printer.

3. Full-automatic control systems are reliable and convenient to operate.

4. Visual graphics control interface, multi-language choice, more intuitive.

5. Control system adopts SIEMENS PLC and touch screen. Frequency converters, weighing sensors, and low voltage electrical devices can also adopt SIEMENS, Toledo, Schneider or Omron, etc.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.