| Model & Capacity | Model: YDHB Series [20 – 80T/H] |

|---|---|

| FOB Price | $40,000.00 – $160,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

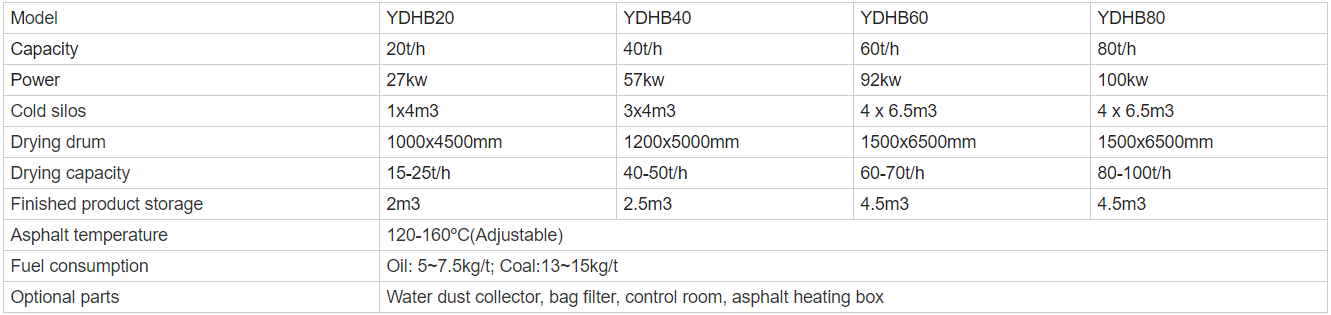

Model and Parameter of Drum Mobile Asphalt Plant

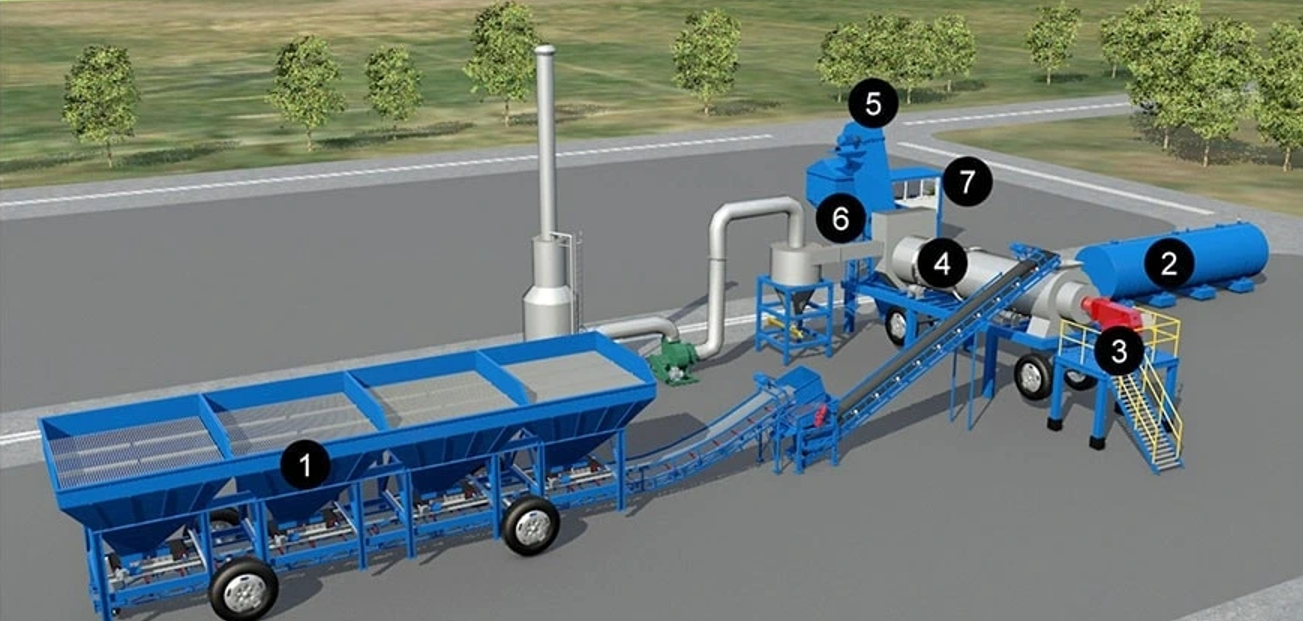

Composition of drum asphalt mixing plant

1. Cold feed system 2. Asphalt system 3. Heating system 4. Drying system 5. The finished material storage system 6. Dust removal system 7. Control system

The mobile drum type continuous asphalt mixing machine is very different from the forced asphalt mixing plant. It adopts the form of drum mixing to continuously dry the aggregate while mixing.

1. Simple structure, modular design, easy to transport and install

2. The investment cost is much lower than the compulsory asphalt mixing plant

3. The drying drum has high drying efficiency and saves energy

4. Scraper conveyor transports asphalt mixture for easy cleaning

5. Multi-functional, optional burner with multiple fuels

6. Fully automatic control system

Features of drum mobile asphalt mixing plant:

1. Container type structure, less floor space;

2. Convenient to move and reorganize; equipped with a mobile chassis, which can be dragged by trucks or tractors to move and change sites;

3. The drying cylinder has the functions of drying, heating, and stirring aggregate, with low production cost and high-cost performance.

4. The operating system can be switched between manual, automatic, and semi-automatic operations.

Cold aggregate grading system

All hoppers are equipped with a belt feeder controlled by a frequency conversion motor, which can adjust the ratio of a single hopper to all hoppers, increase measurement accuracy and reduce energy consumption, wide speed adjustment range, and have high work efficiency. A vibrating motor is installed on the outer wall of the fine aggregate hopper to ensure the reliability of feeding, and a specially designed self-cleaning device is installed. The conveyor adopts a circular belt without joints, which runs smoothly and has a long service life. Optional portable axle, easy to move. The international advanced weighing system is adopted to ensure the accuracy of various aggregates.

Drying system

Reverse drying drum design, high drying efficiency and energy saving. Diesel, heavy oil, coal, natural gas or mixed fuel burners can be used. Optional portable mobile axle chassis.

Dust removal system

The bag dust removal system can control the exhaust gas emission below 20mg/Nm3, ensuring domestic and European environmental protection requirements. The Dopont NOMEX filter bag made in the United States is used, which is resistant to high temperatures and has a long service life. Equipped with an intelligent temperature control system.

Control System

Using German Siemens electrical components, it can be guaranteed to work stably even in harsh production environments. Using Japanese ORMON PLC technology and touch screen operating system, it has high data processing capability and can save various operating data in fact. Multi-language compatibility, the corresponding language system can be configured according to customer needs.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.