| Model & Capacity | Model: YLB Series [60 – 160 T/H] [700 – 2000 KG/BATCH] |

|---|---|

| FOB Price | $40,000.00 – $160,000.00 / Set |

| Price Range | Depend on the different specifications. |

| Payment Term | 30% – 50% T/T in advance, 50% – 70% balance by TT / LC before shipment. |

| Delivery time | It will be shipped within 30 days after receiving the deposit. Negotiable for Busy Season or Large Qty. |

| Warranty | 12 months after shipment or 2000 working hours, whichever occurs first. |

| Transportation | Inquiry us right now to get the complete transportation plan. |

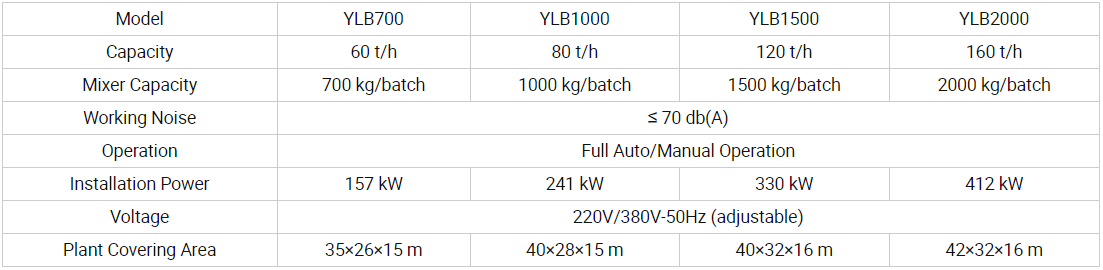

Specifications of YLB Mobile Asphalt Mixing Plant

The biggest feature of the mobile asphalt mixing plant is that it can be transported on wheels. It is also an intermittent forced asphalt mixing plant that can be installed quickly and greatly reduces operating costs.

All parts of the mobile asphalt concrete mixing plant are streamlined in design, convenient, and flexible to move. All aspects of the configuration and facilities are specially designed and manufactured for the mobile asphalt mixing plant. The drying, weighing, mixing, and discharging systems are fully computer-controlled to ensure the accuracy and reliability of the operation of each process. The cold storage bin, the drying cylinder, the weighing, and mixing system, and the bag dust removal system are all movable settings, convenient for transportation, and easy on-site installation.

Features of Mobile Asphalt Batching Plant:

1. Modular design, faster and more convenient for transportation and installation;

2. The mixing blade is unique in design, and the mixer driven by big power makes mixing easy, reliable, and efficient;

3. The vibrating screen driven by the imported vibrating motor greatly improves the efficiency and reduces the failure rate of the equipment;

4. Lifting the aggregate and adopting a double-row plate to increase the service life of the hoist and improve the operation stability;

5. It adopts a dual-machine automatic control computer/manual control system, with an automatic fault diagnosis program, simple and safe operation.

Drying drum system

1. Four sets of famous powerful direct gear motors are used to drive the drying drum;

2. The optimized blade makes the drying process more balanced and the heat utilization rate is higher;

3. The drying drum is covered with heat insulation material and stainless steel skin to prevent heat loss;

4. Well-designed and carefully heat-treated drying drum, world-class bearings have a long service life and stable performance.

Dust removal system

1. Secondary dust removal system, in line with European emission standards;

2. Pulse dust removal method, energy-saving and high efficiency;

3. The key components are durable;

4. Safety protection, intelligent inspection.

Vibrating Screen

1. Rugged and durable, high strength, remarkable screening effect;

2. The screen is easy to maintain and replace, saving time;

3. The frequency and amplitude are perfectly matched, and the classification accuracy exceeds 95%, which can cope with any harsh working conditions, high-temperature resistance, and excellent productivity;

4. The best design to ensure the best screening results.

Mixing System

1. Simulate and optimize the material mixing speed;

2. Ensure that each batch is mixed equally, the mixing efficiency is increased by 25%, and the energy consumption is reduced by 20%;

3. High productivity twin shaft mixer.

We will contact you within 24 hours, please pay attention to the email with the or suffix “@ampunionmachinery.com” or “@daynnmachinery.com”.